|

Soft Starter S801+/S811+

The three-phase motor is currently the optimum drive for simple and economic implementation of machine and system concepts. Nevertheless, a direct-on-line start or a star-delta start is not always the best solution. Soft starters offer the gentle alternative for almost every application for judder free and power network protected motor starts.

S801+/S811+ – Soft Start up to 850 A (1472 A “In-Delta)” Eaton S801+ / S811+

The Soft Starter Family is ideal for applications like pumps, fans and conveyors. Prolonged service intervals and reduced cost of ownership are additional advantages. The Eaton S801+ / S811+ soft starter family delivers solid performance beyond standard protection features found in most soft starters. Choosing a soft starter will increase your productivity and reduce your costs.

Features:

- Compact size, most sizes are the smallest in market, therefore more drives per cabinet are possible

- Eliminating abrupt starts and stops, extending mechanical life of system and reduces service cost for belts and gearboxes

- Better control of motor torque, increasing gearbox and bearing life, reducing belt wear and eliminating water hammer with a special Eaton specific pump algorithm

- Lowering inrush, reducing peak demand charges

- Communication ready - native Modbus® RTU on board, no options required

- Sophisticated monitoring functions: power, power factor, phase currents, phase voltage, device temperature, and more, saving additional measurement equipment and wiring cost

- Overload protection for the motor and the soft starter, preventing device damage, independent if in normal operation or at wrong applications

- Copy&paste keypad, removable user interface , simplifies commissioning and saves time in serial production

Applications:

- Three-phase inductive loads

- Soft motor start in transport and conveying systems

- Smooth pump start reduces loading and wear of the entire system (water hammer)

- Solid-state switching of pumps in the extreme environments of chemical plants and filling stations

- Star-Delta Replacement (especially for motors above 5.5 kW, requiring a current reducing start method)

- Pumps and fans in HVAC Applications

- Water/Wastewater Industry

- Fast and noise reduction control in building applications

- Gentle belt start with fan applications.

S801+ / S811+

Mains connection:

200 – 600 V ±10 %, 50/60 Hz

200 – 690 V ±10 %, 50/60 Hz

Control voltage:

24 V DC

Rating range:

37 – 850 A (at 400 V)

65 – 1472 A (at 400 V In-Delta, S811+ only)

180 – 850 A (at 690 V, S811+ only)

311 – 1472 A (at 690 V In-Delta, S811+ only)

Power feature:

- AC53b, inductive load with internal bypass

- Engineered to industry standards UL, CSA, RoHS, IEC, CE, C-Tick, CSA elevator duty and CCC

- kW and power factor measurement and display

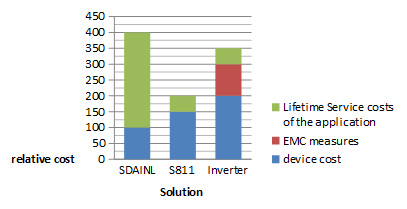

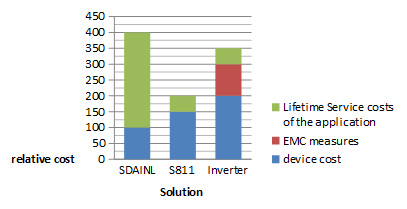

Savings potential:

The reduction of peak-currents and the lower wear of the machine ensures the following comparison between conventional solutions, Soft Starters and Frequency Inverters.

Service costs include costs for device change of aged contactors, belts and gear boxes as well as the cost for different peak load costs.

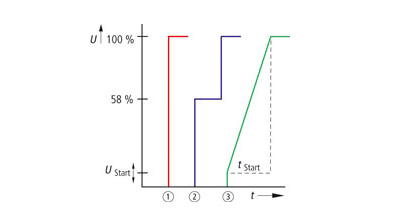

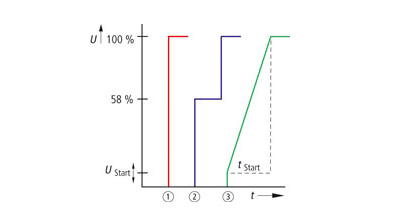

Motor voltage – soft start:

With the soft starter, gating control is used to reduce the motor voltage, then within a predetermined ramp-up time (tSTART), is raised to the mains voltage from an easily-set starting voltage (USTART). In this way, the smooth starting and stopping of the motor protects the mechanical devices connected to it from being subjected to the load with a jolt, and it prevents current peaks and therefore voltage dips in the electrical supply network.

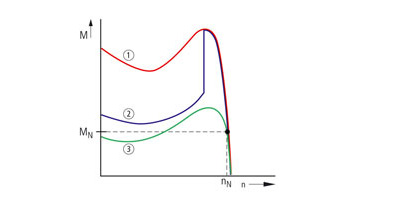

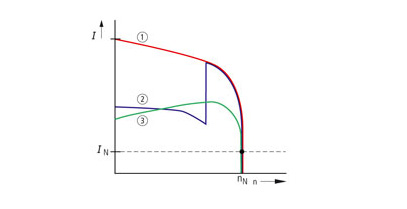

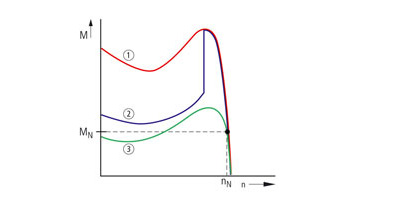

Motor torque – reduced load :

Current and voltage fluctuations during start-up can lead to problems in the network. The resulting abrupt torque fluctuations place stress on machines, necessitating service work and influences on production quality. A soft starter allows you to minimise these disadvantages. It ensures a smoother torque characteristic and reduces your operating costs.

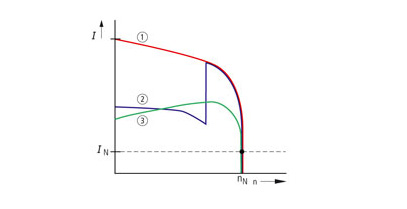

Motor current – damping current peaks:

Power supply companies are demanding increading adherence to certain current limits. The aim is to avoid overloading the network due to high inrush currents during direct-on-line starting or current peaks during star-delta starting, in order to prevent unpleasant side effects such as voltage dips. The reduced voltage start of soft starters eventuates a reduction of peak-currents.

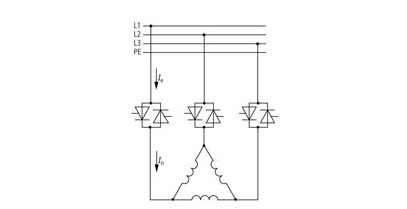

In-line configuration/In-delta configuration (S811+ only)

In-line configuration

Power supply companies are demanding increading adherence to certain current limits. The aim is to avoid overloading the network due to high inrush currents during direct-on-line starting or current peaks during star-delta starting, in order to prevent unpleasant side effects such as voltage dips. The reduced voltage start of soft starters eventuates a reduction of peak-currents.

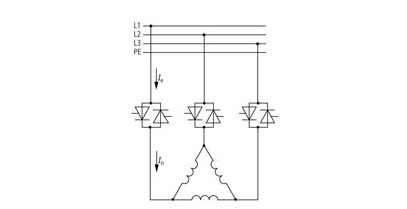

In-delta configuration

Advantages of the „In-delta configuration"

In this circuit configuration, the individual phases of the S811+ are connected in series with the individual motor windings (six conductor connections as with the star-delta starter). The soft starter must only conduct about 58 % of the rated motor current. This facilitates the use of a significantly smaller device.

Other Pictures

|